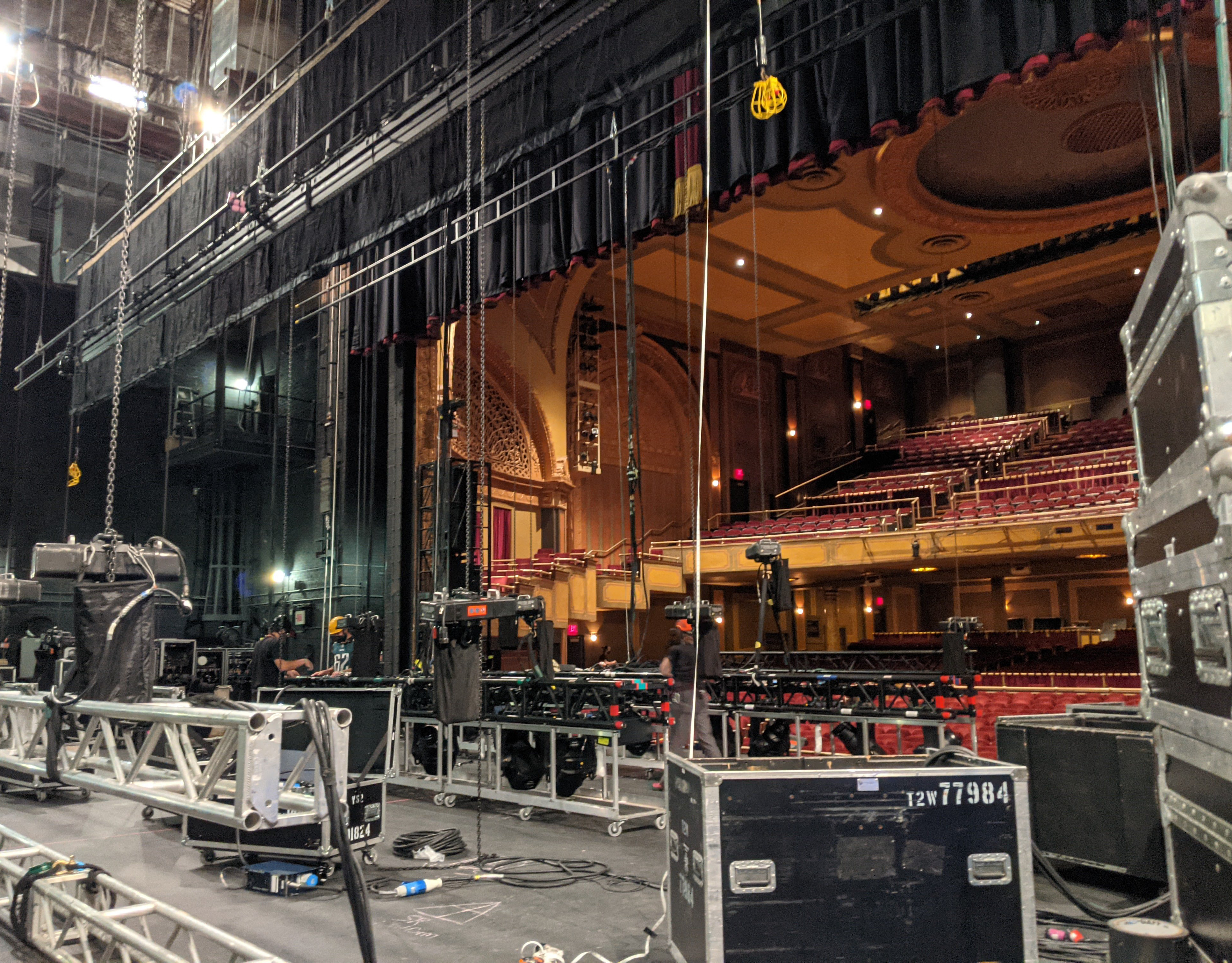

lOAD-iN AND lOAD oUTS

Implemented a new system that reduced weekly load-in and load-out times by more than half.

Lead a crew of 5 to 10 individuals and created specialized positions for each department to prep, inventory, and inspect all equipment upon check-in and check-out.

Worked with Best Boy Grip and Best Boy Electrics to facilitate any equipment needs

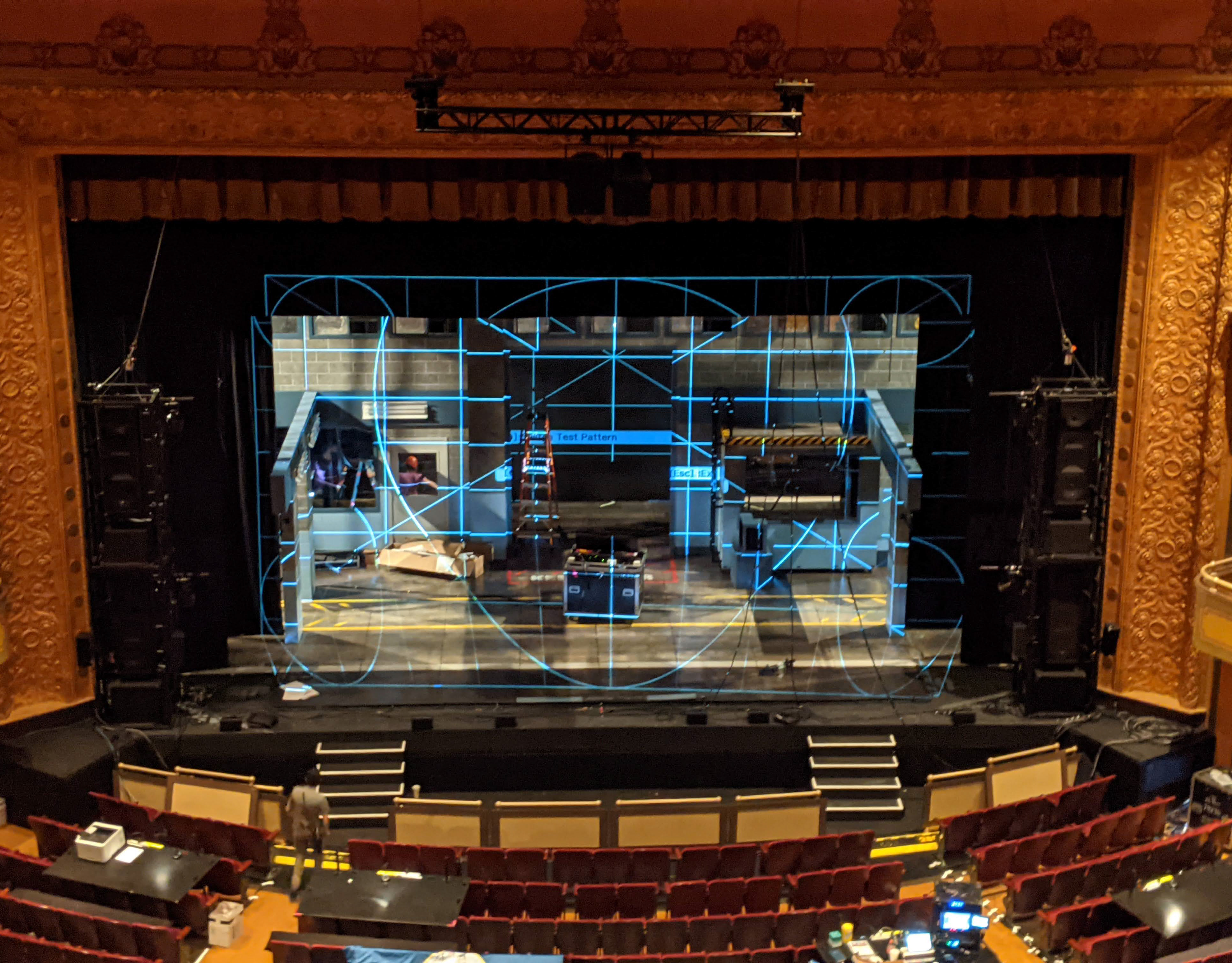

New shop layout

I created clear defined spaces for sound repair, grip repair, storage, and a workshop space that includes general tools, hardware, paint, and other miscellaneous but useful items. Each space was tailored with custom organizational storage for the kind of equipment being stored.

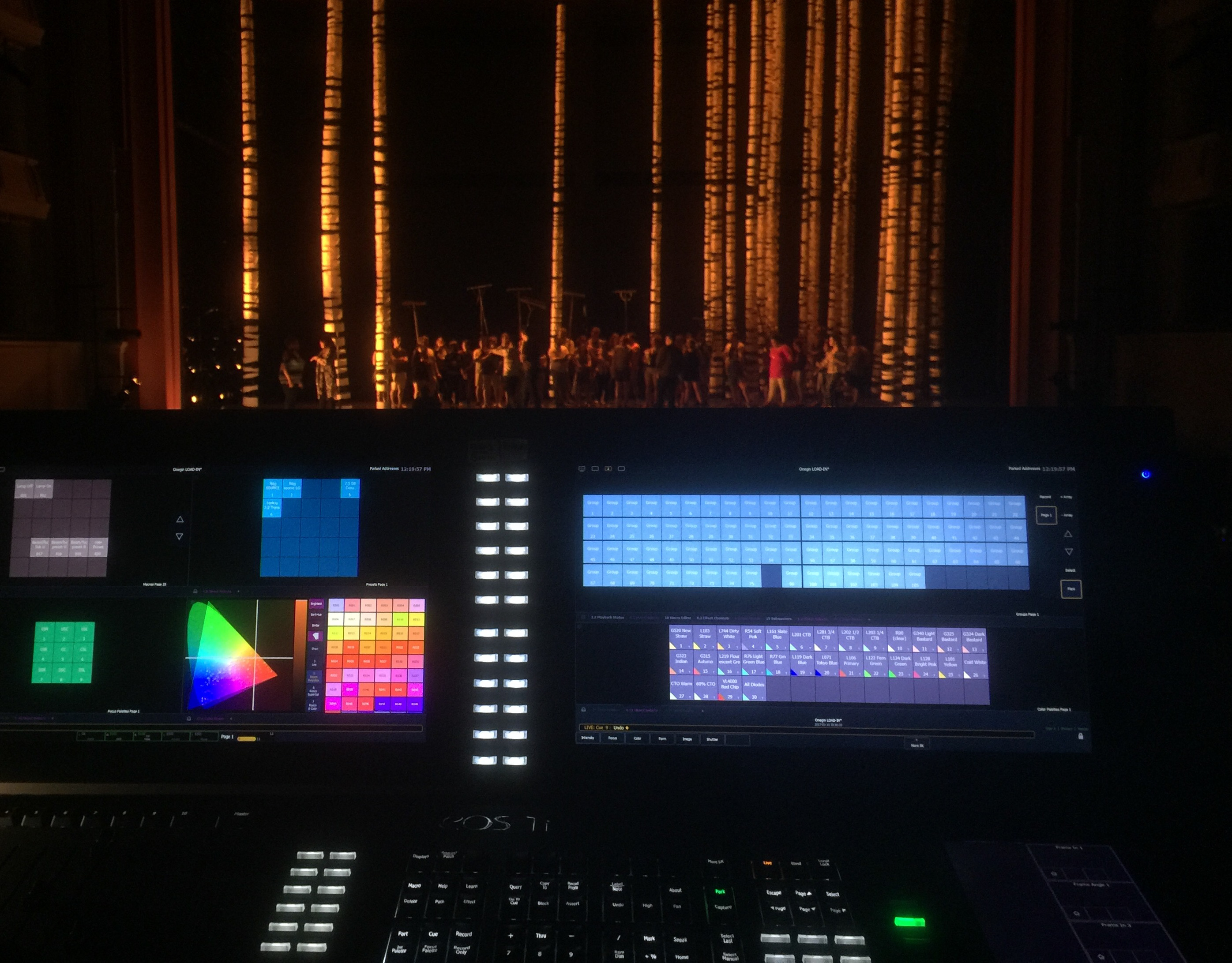

New Specialized Staff

Worked with my employer to hire sound, electrics, and camera personnel. This has cut down on the turn around time of equipment repair. At the time, this also allowed myself to concentrate more on making fundamental improvements on how the shop runs, functions, and how it is set-up.